Post-VFPC update: Catching up with Glove Systems

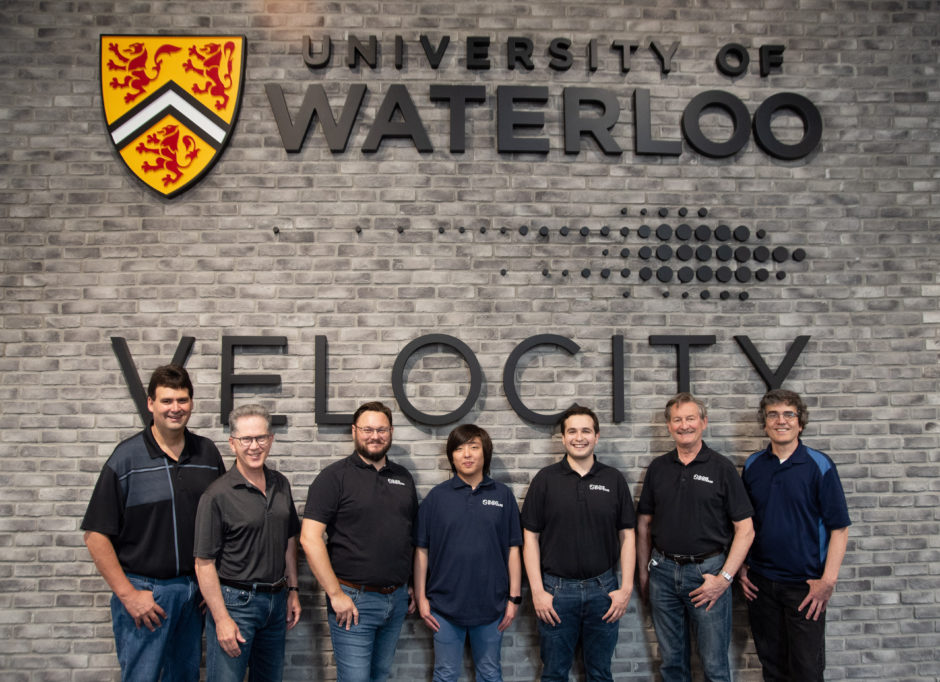

Glove Systems offers an advanced software solution that helps fabricators and project owners to manage risk, improve quality, and enhance productivity. Glove Systems’ core technology is based on the academic work completed by Co-Founder, Mahdi Sharif, during his Masters and PhD degrees along with several other graduate and coop students at the University of Waterloo. This work is backed by years of research from Dr. Carl Haas, a professor at the University of Waterloo and the Tier I Canada Research Chair in Construction and Management of Sustainable Infrastructure. Dr. Haas also serves as the company’s Chairman.

At the inaugural VFPC in March 2019, Glove Systems became a Velocity portfolio company, becoming one of the first high potential startups to receive $50,000 of pre-seed capital from the Velocity Fund.

We recently caught up with Glove Systems to learn more about their progress since that VFPC and how they are positioned to revolutionize the multi-billion-dollar industrial fabrication industry.

The following has been edited for clarity.

Q: How has your company developed since receiving an investment at VFPC?

Receiving the investment, along with perfecting our pitch, led us to find our first few angel investors. With the funds we raised, as well as some further investments, we were able to finish the first version of our product – our cloud-based quality control platform – and acquire our first customers.

Q: What is your company currently working on?

We are working on getting more customers using our software as a remote inspection platform. With travel becoming harder, we are seeing great interest in our software from fabrication shops and project owners. Our software can help increase visibility into their supply chain, while improving safety and reducing travel and human traffic in fabrication shops.

We are also working on the next generation of our product, where we will add new QC [quality control] functionalities.

We are working on an NGen project with Black Powder Solutions, a customer of ours. BPS fabricates magnetic separators that remove over 95% of black powder contamination from hydrocarbon fluid and gas streams. BPS is using Glove Systems quality control platform as a remote inspection tool to give confidence to their clients that when their pressure vessels arrive at the site, they will have no fitting issue and no rework.

Q: Can you tell us more about NGen and the nature of the project? Some of our readers may not be familiar.

NGen is Next Generation Manufacturing Canada. The Government of Canada set up NGen as a part of the superclusters strategy to drive innovation and bring new manufacturing technologies and capabilities forward in the Toronto-Waterloo corridor and the rest of Canada.

We are a member of NGen. Our product is an advanced manufacturing tool so the project is supporting Black Powder Solutions in that regard. We can help make Canadian manufacturing much more competitive globally, and we hope to work with more Canadian fabricators, project owners, and manufacturers to accomplish that.

Q. What are your major strategic goals in the next 12 to 18 months?

Our primary goal is to become the gold standard, de facto QC tool used by fabrication shops and manufacturers.

Our industry is changing. To increase quality, safety, and productivity, more and more projects are getting done with prefabrication and modularization methods. This means that the majority of the fabrication of components is taking place in fabrication shops, away from the actual construction sites. Hundreds of billions of dollars are spent in North America in prefabrication alone, but defects such as geometric deviations are costing the industry between $10 to $20 billion annually. With our technology, the fabricators can ensure quality and provide confidence to the project owners through increased supply chain visibility.

Q. How do you think your industry/field will evolve in the next 5 years?

There is a huge push in the industrial fabrication industry to become digitized at all stages of the process. Our company is focused primarily on digitizing quality control. This digitization, referred to as digital twins, will enable fabricators to be more accurate, and project owners to have more insight into their projects, supply chain, and many other benefits.

Of course, the importance of this trend has increased because of COVID-19. The industry standard practice of sending QC personnel to construction sites and fabrication shops for inspection is now an unsafe practice. Businesses are forced to think differently and figure out new business processes while being safe, and we think we can help with that.

Q. What are some of the best opportunities on the horizon for your company?

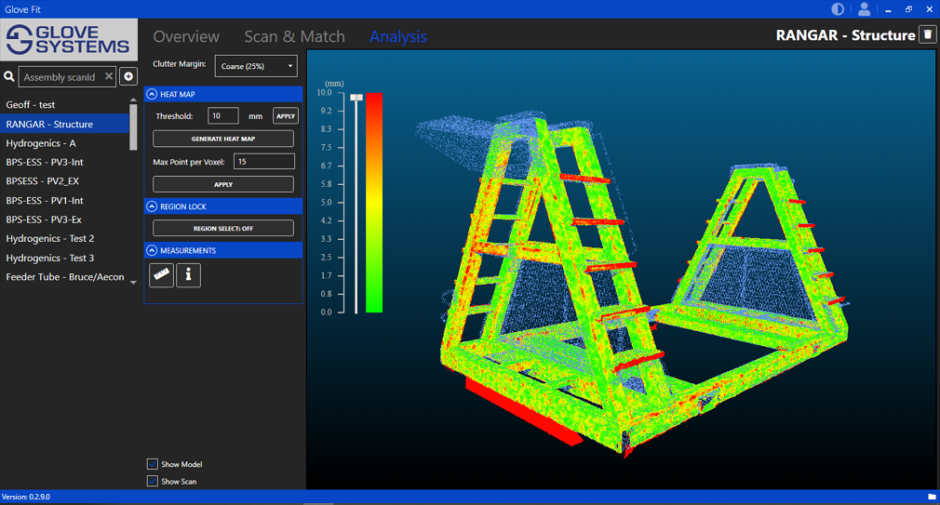

We are talking with fabrication shops, manufacturers, and project owners. We are uniquely positioned to become the gold standard of an easy-to-use quality control and inspection platform for the industrial construction market too. As an example, RANGLAR Manufacturing, a global manufacturer of heavy industrial vehicles, is using our QC platform in their fabrication shops for providing remote quality control to their clients.

Q. What do you enjoy most about building a startup?

I think there is something satisfying in taking an idea, working on it for years, and seeing it grow with you. When I look back at where we started and where we are today, I am amazed by the amount of progress that we have made.

I think having a startup is the most efficient way to see your idea grow, as well as achieving growth yourself.

Q. Are there any tips you can give startups looking for an investment from Velocity?

Clear your IP first. Because our company’s IP was generated at the University of Waterloo, we had to clear our IP and it was one of the most challenging things at the beginning of our startup journey. It was a painful 2-year process. We had a lot of help from Velocity and the University itself to make it happen though. I guess now that we’ve done it, you can reach out to us (Editor’s note: specifically Mahdi Sharif) for help.

Q. How about tips for those who get to the final stage where they have to pitch?

Practice, practice, practice. And do not be afraid of failing. I also think that the process is more important than the actual pitch. The process of distilling your idea to 3 minutes is a hard and important process.